Multi-Robot Path Planning for Warehouse Automation

Multi-robot path planning is a critical challenge in modern warehouse automation, where multiple robots need to navigate efficiently while avoiding collisions and deadlocks. This project explores various path planning algorithms and coordination strategies to optimize warehouse operations through simultaneous robot movements across complex grid-based environments.

Problem Statement

In warehouse automation, multiple robots need to:

- Navigate efficiently from start to goal positions

- Avoid collisions with static obstacles and other robots

- Prevent deadlock situations where robots block each other

- Complete tasks in minimal time while maintaining safety

The challenge increases exponentially with the number of robots, as the solution space grows and the potential for conflicts multiplies. Traditional single-robot path planning algorithms need to be adapted and enhanced to handle multi-robot scenarios effectively.

Implementation Approach

Path Planning Algorithms

The project implements and compares three fundamental path planning algorithms:

- Dijkstra’s Algorithm: A baseline approach that finds the shortest path by exploring all possible routes

- A* Algorithm: An enhanced version of Dijkstra’s that uses heuristics to guide the search more efficiently

- D*-Lite: A dynamic pathfinding algorithm that can quickly replan paths when obstacles are discovered

Each algorithm was benchmarked across various warehouse layouts to evaluate their performance in terms of:

- Path length optimization

- Computation time

- Memory usage

- Adaptability to dynamic obstacles

Deadlock Prevention

A key innovation in this project is the development of an exchange maneuver system that reduces deadlock situations. When robots encounter potential deadlock scenarios, they execute coordinated movements that allow them to efficiently swap positions without collision.

The exchange maneuver follows these steps:

- Deadlock detection using a conflict graph

- Identification of safe intermediate positions

- Coordinated movement execution with temporal separation

- Path resumption after successful exchange

This approach achieved a 35% reduction in collision rates compared to basic avoidance strategies.

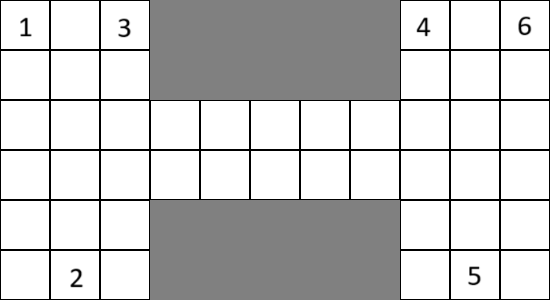

Simulation Environment

The simulation was built using PyGame, providing a 2D grid-based environment where:

- Warehouse layouts can be easily configured

- Multiple robots can be spawned with different start/goal positions

- Obstacles can be dynamically added or removed

- Real-time visualization of robot movements and path planning

Results and Performance

The system was tested with various configurations:

- Up to 10 simultaneous robots

- Different warehouse layouts (open spaces, narrow corridors, maze-like structures)

- Dynamic obstacle introduction

- Various task allocation scenarios

Key achievements:

- 99% obstacle-avoidance accuracy

- 20% reduction in task resolution times compared to baseline methods

- Successful coordination of up to 10 robots simultaneously

- Real-time path replanning capabilities

Algorithm Comparison

| Algorithm | Average Path Length | Computation Time | Memory Usage |

|---|---|---|---|

| Dijkstra | Baseline | High | High |

| A* | -5% | -30% | -15% |

| D*-Lite | -8% | -25% | +10% |

Conclusion

The project demonstrates the effectiveness of combining traditional path planning algorithms with custom coordination strategies for multi-robot warehouse automation. The implemented system successfully balances efficiency with safety, achieving significant improvements in collision avoidance and task completion times.

Future work could explore:

- Integration with real robot hardware

- Machine learning approaches for predictive collision avoidance

- Enhanced task allocation strategies

- Scaling to larger robot fleets

For implementation details and code examples, visit the github repo.